The global logistics and supply chain sector, the engine that powers modern commerce, is undergoing a revolutionary transformation driven by robotics and advanced automation. Faced with ever-increasing consumer demands for speed (next-day or even same-day delivery), chronic labor shortages, and the imperative for cost reduction, traditional human-centric workflows are no longer sustainable. Robotics is the strategic answer, moving the industry from labor-intensive, error-prone processes to highly efficient, scalable, and intelligent automated systems. This integration of autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and sophisticated robotic arms is not merely an optimization; it is the defining feature of the next-generation supply chain, enabling unprecedented levels of throughput and operational resilience.

This extensive guide delves into the specific technologies driving the robotics revolution in logistics, analyzes the profound impact on key operational areas (warehousing, fulfillment, and last-mile delivery), examines the critical challenges of integration and human-robot collaboration, and charts the future of the autonomous, self-managing supply chain.

The Robotics Spectrum: Types of Automation

The term “robotics” in logistics encompasses a diverse array of automated tools, each designed to solve specific, high-volume, repetitive, or strenuous tasks within the warehouse and distribution network.

1. Autonomous Mobile Robots (AMRs)

AMRs represent the cutting edge of logistics automation, utilizing advanced sensors, onboard computing, and Artificial Intelligence (AI) to navigate dynamic environments.

- A. Flexible Navigation: Unlike older AGVs, AMRs do not require magnetic strips or predefined pathways. They build and update internal maps of the facility in real-time, allowing them to dynamically route around obstacles (people, forklifts, fallen items) without stopping the operation.

- B. Task Versatility: AMRs are used for a variety of tasks, including transporting goods (totes, pallets), acting as mobile shelves for “Goods-to-Person” systems, and facilitating cycle counting for inventory management.

- C. Human Collaboration: AMRs are specifically designed to safely operate alongside human workers, enhancing productivity by taking over the tedious task of walking long distances for fetching items.

2. Automated Guided Vehicles (AGVs)

AGVs are the predecessors to AMRs and remain highly effective for large-scale, repetitive tasks in predictable environments.

- A. Fixed Path: AGVs follow fixed routes, typically guided by wires embedded in the floor, magnetic tape, or laser navigation systems.

- B. High Load Capacity: They are ideal for moving heavy, standardized loads, such as large pallets or entire racks, reliably over long, unchanging distances within a facility.

- C. Safety Protocols: AGVs operate with rigorous safety protocols, using sensors to stop immediately if an obstruction is detected on their fixed path.

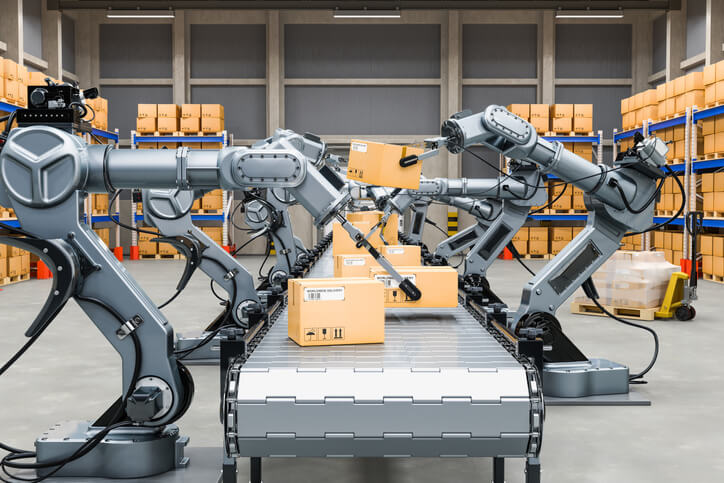

3. Articulated Robotic Arms (Picking and Packing)

Robotic arms, often seen on manufacturing lines, are increasingly deployed in the highly variable environment of e-commerce fulfillment.

- A. Advanced Vision Systems: These arms are paired with sophisticated 3D vision systems and deep learning algorithms that allow them to identify, orient, and grip a near-infinite variety of products (size, shape, texture)—a key challenge in e-commerce packing.

- B. High-Speed Sorting: Robotic arms are used for rapid induction into sortation systems and for placing items into shipping cartons, achieving cycle times and consistency far exceeding human capability.

- C. Ergonomic Relief: They automate the repetitive, high-strain movements associated with continuous picking and placing, reducing workplace injuries.

4. Automated Storage and Retrieval Systems (AS/RS)

AS/RS are large-scale, capital-intensive systems designed for high-density storage and rapid retrieval.

- A. Vertical Density: These automated cranes and shuttles maximize the use of vertical space, drastically reducing the physical footprint required for storage.

- B. High Throughput: AS/RS systems can retrieve specific stock-keeping units (SKUs) and deliver them to human pick stations with exceptional speed and accuracy.

- C. Shuttle Systems: Modern micro-shuttles can operate independently on multiple tiers of racking, providing highly modular and scalable dense storage for smaller e-commerce items.

Robotics Transforming Key Logistics Areas

Robotics Transforming Key Logistics Areas

The deployment of robotics is fundamentally restructuring the processes within warehousing, fulfillment centers, and the final delivery stage.

A. Warehousing and Inventory Management

Robots are creating “dark warehouses” where lighting and environmental conditions are optimized for machine, not human, operation.

- Goods-to-Person (G2P): This is a cornerstone of robotic efficiency. Instead of a human walking miles per day to fetch items, AMRs bring the inventory racks or shelves directly to the human worker (the “picker”), dramatically reducing travel time and boosting pick rates.

- Autonomous Putaway: Robots autonomously place returned or newly received inventory back into the optimal storage location based on data-driven metrics (e.g., proximity to other popular items, current demand forecasts).

- Real-Time Cycle Counting: AMRs equipped with RFID or vision systems can roam the warehouse continuously, autonomously scanning inventory locations and updating the Warehouse Management System (WMS) in real-time, ensuring inventory accuracy is near 100%.

B. E-commerce Fulfillment and Packing

The explosive growth of e-commerce necessitates automation to handle the extreme variability of small, mixed orders.

- Automated Order Consolidation: Robots can take items picked from various parts of the warehouse and efficiently consolidate them at a central packing station, minimizing human effort in handling disparate items.

- Dim Weight Optimization: Advanced robotic systems, often powered by AI, can select the smallest viable shipping box for a mixed order, a process known as “cubing”. This minimizes “dimensional weight” shipping costs, which is a major expense for logistics companies.

- Custom Labeling and Manifesting: Robotic applicators automatically apply shipping labels, customs documentation, and sorting manifests with pinpoint accuracy and high speed, integrating directly with carrier systems.

C. Last-Mile Delivery and Transportation

Robotics is beginning to impact the final, most expensive leg of the supply chain journey.

- Autonomous Delivery Vehicles (ADVs): Small, sidewalk-based robots or larger autonomous vans are being piloted in urban and campus environments to deliver parcels directly to the consumer’s doorstep. These solutions solve traffic congestion challenges and reduce labor costs in dense areas.

- Drone Delivery Systems: While regulatory hurdles remain, drones are being deployed for highly specialized, urgent deliveries (e.g., medical supplies in remote areas) where speed is paramount, offering a powerful vertical logistics solution.

- Truck Platooning and Yard Management: Large-scale automation in the yard includes autonomous yard trucks (AMRs) that move trailers between the loading dock and staging areas, and eventually, autonomous platooning of semi-trucks on highways, which improves fuel efficiency and reduces driver fatigue.

The Economics and ROI of Robotics Integration

The high initial capital expenditure (CAPEX) for robotics must be justified by long-term gains in operational efficiency and resilience.

A. Cost Reduction Metrics (The ROI Drivers)

The return on investment (ROI) for logistics robotics is realized through several key performance indicators (KPIs).

- Increased Throughput: Robots operate 24/7 without breaks, significantly increasing the volume of orders processed per hour, often by 2x to 5x compared to manual processes.

- Reduced Labor Costs: While robots do not eliminate jobs, they significantly reduce the dependence on high-cost, high-turnover manual labor for repetitive tasks, allowing human workers to be reskilled for higher-value jobs (e.g., maintenance, supervision, exception handling).

- Accuracy Improvement: Robotic systems operate with near-perfect accuracy, driving order fulfillment error rates down to less than 0.1%, which drastically reduces the cost of returns, mis-ships, and customer service resolution.

B. Strategic Resilience and Scalability

Beyond immediate cost savings, robotics provides critical strategic advantages.

- Seasonal Scaling: Robotic fleets can be scaled up or down rapidly—either by adding more units or optimizing existing units—to handle massive, unpredictable peaks in demand (e.g., Black Friday or holiday shopping seasons) without hiring and training temporary staff.

- Operational Consistency: Robots provide consistent, predictable performance regardless of external factors like labor shortages, pandemics, or fluctuating economic conditions, ensuring supply chain resilience.

- Land Use Efficiency: AS/RS and dense robotic systems maximize vertical density, reducing the square footage required for a facility, lowering property and construction costs.

Challenges and The Future of Human-Robot Collaboration

Integrating robotics into existing, complex logistics operations presents unique technical, human, and ethical challenges.

A. Integration and Software Complexity

Robots are useless without seamless integration into the facility’s existing technology stack.

- WMS/WES Integration: The robotic fleet management system must communicate flawlessly and in real-time with the Warehouse Management System (WMS) and Warehouse Execution System (WES) to receive tasks, report status, and confirm inventory movements. This requires robust API development and system customization.

- Fleet Management: Managing hundreds or thousands of mobile robots requires sophisticated AI-driven software to orchestrate traffic flow, allocate tasks, manage battery charging cycles, and prevent collisions—a challenge far exceeding single-robot programming.

- Maintenance and Downtime: Robotics introduce new maintenance complexities. Specialized technicians are required to service the mechanical, electrical, and software components, and any downtime in an automated system can halt an entire operation.

B. The Reskilling Imperative (Collaboration)

The deployment of robotics fundamentally changes the skill requirements for the logistics workforce, necessitating a strategic focus on human-robot collaboration.

- New Roles: The industry shifts from “pickers” to “robot supervisors,” “data analysts,” and “maintenance technicians.” Workers need training in robotics operation, system diagnostics, and exception handling (managing orders the robots cannot complete).

- Safety and Interaction: Protocols must ensure the safe and ergonomic interaction between humans and autonomous machines, fostering trust and efficiency rather than fear and collision risk.

C. Ethical and Societal Implications

The growth of autonomous logistics raises important ethical questions regarding job displacement and data privacy.

- Job Transition Planning: Companies have a societal responsibility to invest in reskilling programs that transition their existing workforce into the new, higher-value, technology-enabled roles created by automation.

- Data Security: The massive amount of real-time data collected by robotic fleets (inventory, movement patterns, efficiency metrics) requires robust cybersecurity protocols to prevent espionage or operational sabotage.

- Regulatory Harmonization: Governments must develop standardized regulations for autonomous vehicles (ADVs and drones) to ensure safety and public acceptance for last-mile robotic delivery systems.

Conclusion: The Autonomous Supply Chain

Conclusion: The Autonomous Supply Chain

Robotics is no longer an optional investment but a required evolutionary step for any logistics operation aiming for survival and dominance in the 21st century. The confluence of highly intelligent AMRs, advanced vision-guided robotic arms, and dense AS/RS is creating a supply chain that is faster, more accurate, and more resilient than ever before. This transformation is driven by the strategic need to meet customer expectations while managing labor and cost pressures. While the transition demands substantial initial investment and rigorous system integration, the ultimate reward is the creation of a truly autonomous supply chain, one that learns, adapts, and executes with a precision that human-centric logistics simply cannot match, solidifying robotics as the indisputable future of global commerce.